Our history

23 november 1992

«Selena» LLP was created. Manufactured products: copper sponges for electromagnetic contactors and wipers for long-distance ERS. The first customers were the tram-trolleybus parks of selected cities of the Russian Federation, Kazakhstan, and the Baltic countries.

All the founders of «Selena» LLP studied at MIIT and then worked at VNIIZhT, researching the problem of current-collecting. Researches were conducted to identify optimal contacting pairs of materials.

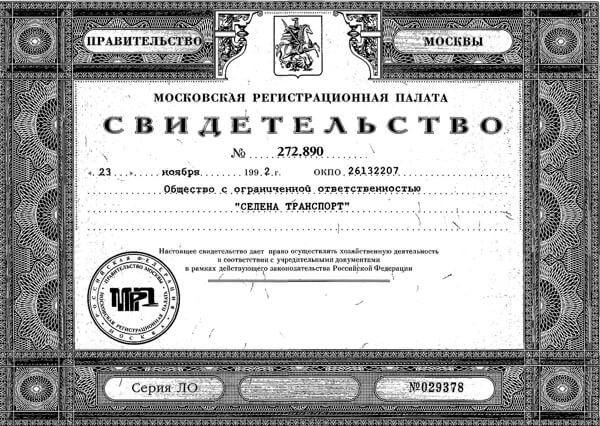

The certificate of the Moscow Chamber of Registration on the establishment of a legal entity «Selena Transport»

1994

The results of our researches were technologies for making contacts based on copper, which were proposed and then put in the MLRZ.

1995

«Selena» LLP was re-registered with «Selena Electric Transport» CJSC. We placed orders for products manufacturing at the electromechanical factory by Pushkin, Tula Arms Plant and the company «Polimash». The product range has expanded with the release of various kinds of collectors' runners for all types of ERS at that time. We also delivered delivery of products to railways and to electric locomotive repair plants throughout Russia.

1995, Tula Arms Plant

1998

The team increased to 10 people working on the production of the most advanced technological solutions for current collection from the contact network at that time.

1998, EP1 — the first serial six-axle passenger locomotive

Experimental drawings were developed, many tests of equipment designs were carried out.

2001—2002

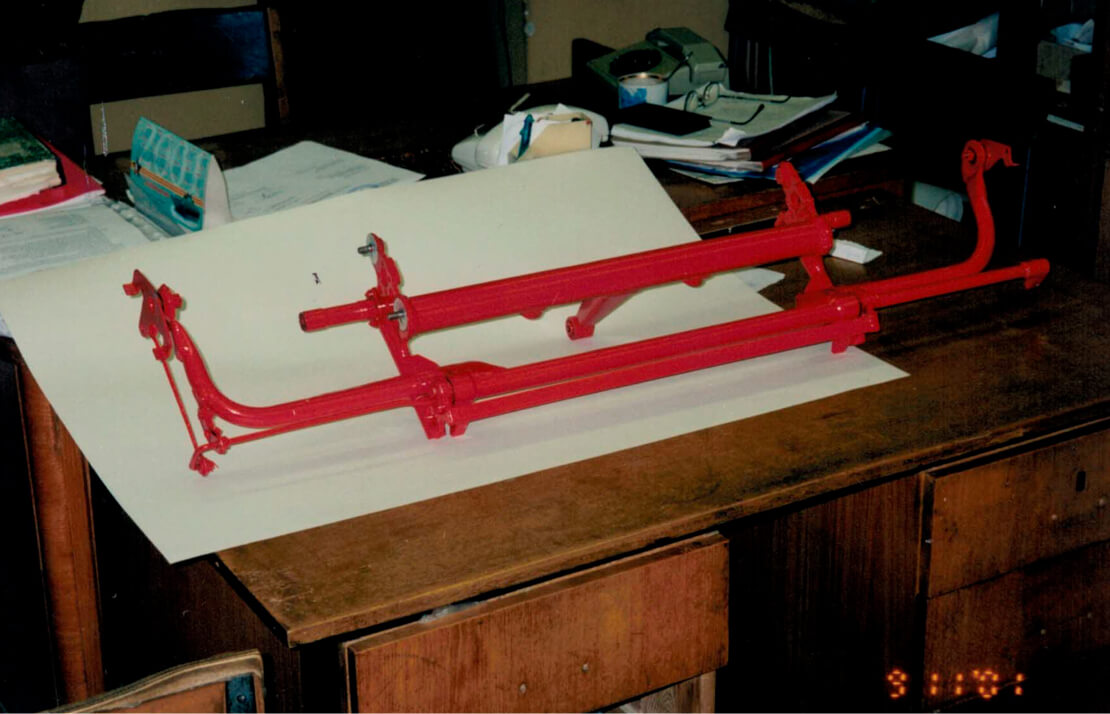

«Falcon-250»

Work began on a dual-use current collector device, as it was required to solve the problem of supplying the electric train with both alternating and direct current.

2001, Asymmetric current collector for the project «Falcon-250»

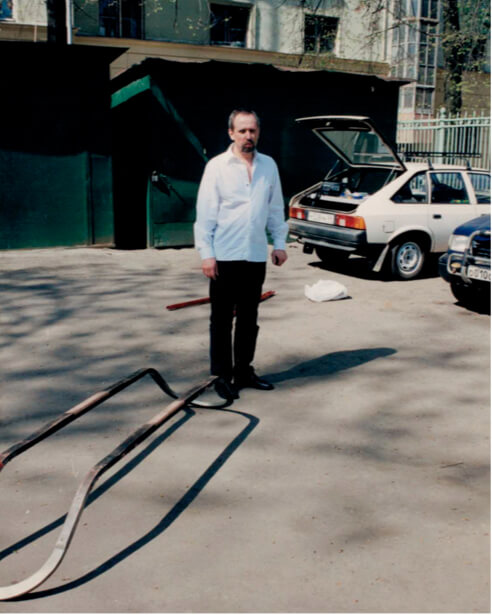

2001, Gukov M.A. near ES250

In June 2001, at the stretch of railroad track, the Doroshikha-Lihoslavl electric train set a speed record of 236 km / h.

Unfortunately, with the existing design, the current collector TP-250 cannot be used for continuous exploitation. The project itself did not pass the test, during which revealed 25 critical flaws of the electric train model. In the future, a model of that current collector formed the basis for the design of most of the models produced until today.

2002

Development of current collectors and runners for «ChS200»

On serial models (003 through 012), instead of the asymmetrical current collectors «AM18U» of the French company Fevlei, installed on prototypes, on serial locomotives «66E1» were installed domestic symmetrical two-stage current collectors of TSP-6th which was developed by I. A. Belyaev and V. A. Shiyan, whose design was parallel tested on the electric train ER200.

ChS200-001 at the last preparations for transportation to the USSR

ChS200-003 in serial production with our current collector

2002, Mironos N.V. near a runner for the TSPth current collector

In that year, our team began the detailed development of an experienced current collector

2002 — 2004

Our team of «S-Electric transport» was gradually replenished with valuable personnel. We provided test trials of the latest current collector models, and we also attended conferences of the expert community, we shared and received valuable experience.

In 2003, the supply of runners began centrally in Roszheldorsnab through competitive bidding.

2005

The company began production of current collectors for electric rolling stock. Deliveries were made at JSC «UZZHM» and in small quantities on Ekaterinburg and West-Siberian railways. We decided to create our own production. Firstly, due to the difficult logistics of obtaining components. Secondly, due to delays in the supply of accessories.

2007, 2ES6-001 — the first train of the series with our current collector

2006 — 2010

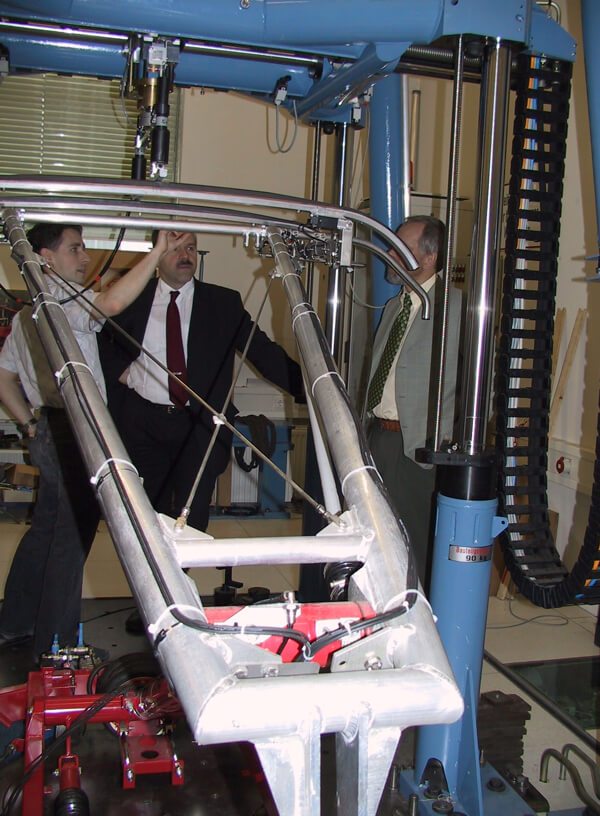

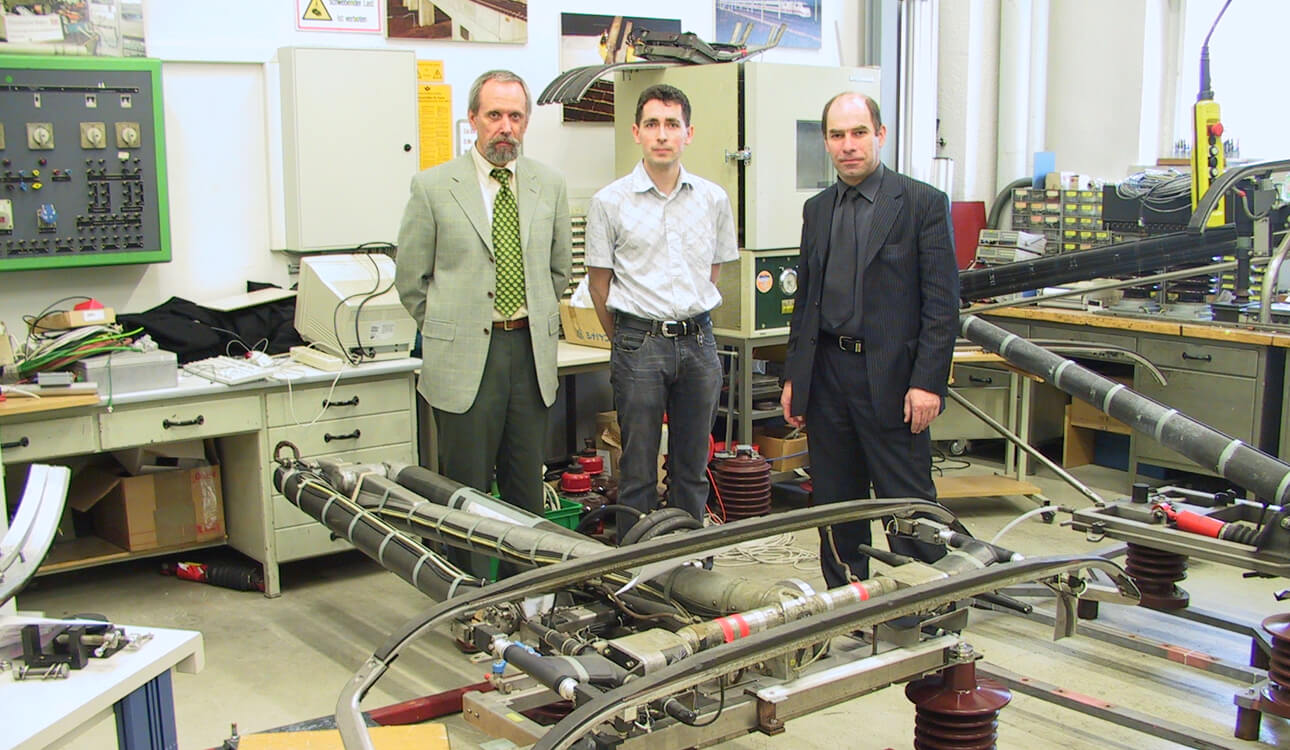

April 2009, DB «Systemtechnik», Germany

Myronos N.V. with partners in Germany were testing a new model of a current collector.

2011

We began to cooperate with the LLC «STM-Service». We supply current collectors, spare parts for the repair and technical maintenance of diesel locomotives.

2013

The laying of the foundation of the new workshop and the beginning of the construction of the «S-Electric transport» complex.

2014

We have passed the international certification of «IRIS».

The goal of the standard is to create a business management system that allows continuous improvements, emphasizing the prevention and reduction of the number of defects in the supply chain.

2016, Extended Certificate «IRIS»

2015

The new workshop was fully ready and began to function. The stage of preparation of neighboring areas for the construction of new branches of production began.

June 25, 2015, Sofrino. Completion of the construction work of the production department

The first tests of current collectors for the «Swallows» began.

2016

The area of the production workshop was increased by 200 sq.m. On the new square, it is planned to place a CNC tube bender.

A contract was concluded with LLC «RTKS» (in 2017 renamed to LLC «RailAlliance») for the supply of current collectors for the EP2D direct current electric train.

Made the first experienced model to combat icing.

Made the first experienced model to combat icing.

2017

The pipe-bending workshop was opened. We changed the arrangement of machines and equipment at the main production workshop with the aim of optimizing the manufacturing technology of current collectors. We also entered into an agreement with «RailAlliance» LLC for the supply of current collectors for the EP3D alternating current electric train.

2018-2021

Our team has created the first Russian tram current collector with an aluminum structure for moving frames. We have also developed and put into operation tram current collectors with an automatic emergency lowering system.

We introduced the concept of a charging device for electric buses in accordance with international standards (SAE International), along with a current-receiving device (the "Astra" receiving system).

2022

At our production facility, we manufactured a prototype of the charging device (CD), and conducted operational tests in collaboration with the State Unitary Enterprise "Mosgortrans" and JSC "KAMAZ". We have started supplying serial CD products to the factories of JSC "NEFAZ" and LLC "LiAZ" for the needs of Moscow. We have also started collaborating with manufacturers of charging stations for electric buses and supplying "Astra" receiving systems.

2023

Our production has expanded, and we have updated our machine park. This year, we began constructing new workshops and also increased the production area by 2500 square meters.